Installing balasine with your own hands Ladder

Balaasins are the main parts of the railing - support racks. The manufacturer of BALASIN is a rather complicated technological process that requires a considerable tolly skills and special equipment. The lathe is installed far from everyone at the site. Therefore, consider only the issue of installing Balyasin.

Content

- Wooden bales: what kind of breed to choose

- Wooden bassines: how to install with your own hands

- So, how is the installation of BALASIN on the stairs?

- Metal balusters

- Metal balusters: how to install with your own hands

- Concrete bassines: how to make

- Concrete bales: how to install with your own hands

- Conclusion

Wooden bales: what kind of breed to choose

Architectural elements from wood are recognized as the most popular and attractive. However, not all wood breeds are good for these purposes. For example, solid rocks are used for the manufacture of wooden racks. We list the advantages and disadvantages of various wood:

1. Oak.

Installation of oak balaasine and railings - the usual case for carpenters. The oak is characterized by high wear resistance and durability, as well as resistance to insects. Oak parts of the stairs do not block and do not succumb to cracking. The density of the breed allows you to create small parts with high detail.

2. Beech.

For quality indicators, the beech only is a little inferior to the oak. At the same time, the beech bends, as a result, is easily processed. In combination with various impregnations, the beech rafters will be launched by a single decade. Without auxiliary compositions, the breed will be guaranteed to rot and breed.

3. Ash.

According to external signs, the ash reminds Oak, but is inferior in strength and density. The advantages of the breed are durability and resistance to rotting.

4. Birch.

This breed is rarely used in view of a tendency to cracking, substantial sweep and rotting. In this case, the tree is perfectly processed, polished. When skillfully stained the birch will be on the nut, red tree or maple.

5. Pine.

Wood is easily grinding, cutting. Installation of wooden balasine from pine - optimal solution. Pine perfectly transfers temperature drops, has high resistance to fungi, the color varies from light to red.

6. Larch.

But the best option will be railing and bales from larch. Wood exceeds oak strength. What is curious, with a certain period of time, the breed becomes stronger due to the unique composition of the resin. This is a durable and practical material.

Wooden bassines: how to install with your own hands

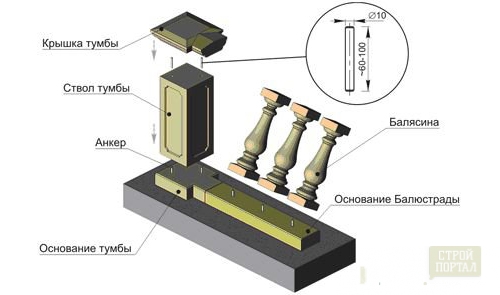

Balaasins From larch or pine are installed on Kosur, the tutor or stairs. Anchor, hardware or specially designed brackets are used for attachment. Moreover, it is extremely important to follow the rules:

- The step between the bassines should be no more than 150 mm.

- Initially, the coasters are installed at the corners, at the beginning and end of the stairs.

- The pillar height should be at least 90 cm.

- It is impossible to mount the wood with nails, which will lead to the screenshots and discrepancies of the parts.

- It is necessary to perform holes in the ends before installing the balasine onto a wooden staircase. The recesses at the base of the supports with a diameter should be 2 mm less than the fasteners.

So how to produce installation of Balyasin on the stairs?

For installation, it is necessary to purchase metal studs with a length of 60 to 100 mm and a cross section from 6 to 10 mm. Also suitable wooden ducts with a length of up to 80 mm with a diameter of up to 14 mm. Poles will be fixed with fastener relatively larger.

- To begin with, marking steps to search for points on which balusters will be attached. In the installation site of wooden columns, screw the screws.

- Then stretch the line through all the screws. It will serve as a reference point for marking. By means of the square, run axial lines and determine the centers of the columns.

- Make a thin drill deepening under each balaasine. Experiment recesses to a diameter of 5 mm using a device for perpendicular drilling.

- Snap the nuts on the end of the hairpin and screw. Do it with all racks and pillars.

- Screw the racks in the deepening steps. Before fixing, check the distance between the racks.

- Installing a baluster with your own hands marked with the fastening of the handrail. On video it is clearly seen how the markup is made to cut the racks.

- It should be cut off the top of the front balossine under the required angle. Then make a long rail and spread the cut line on other columns.

- Wake up the location of the cut with furniture scotch. It will protect the wood from the formation of chips during the cutting process. Cut all the pillars.

- Attach the companion rack by self-drawing. She will perform as the basis for the handrail.

- Cut the ends of the handrail so that everything is tightly fixed. From the opposite end, cut the niches for fixation.

- Secure the handrail to the subsequent rail with the help of self-tapping screws. A decorative lining is suitable for masking caps from self-sufficiency.

Metal balusters

Metal balusters unlike wooden are more durable and durable. With the original processing, metal elements look very attractive, especially in combination with a stone or glass. An extremely exquisite looks forged bales.

But the most popular is recognized as balusters and stainless steel railing. They are not subject to corrosion, allow to achieve seamless elements. At low temperature, the metal is not deformed, as it happens with the tree.

Sufficient decoration of the site will be cast iron bales. According to aesthetic perception, cast-iron elements of the interior or exterior are not inferior to wrought iron. Cast iron allows you to use various fasteners:

- welding;

- concreting;

- threaded mounts.

Metal balusters: how to install with your own hands

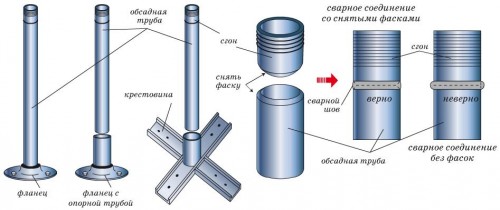

Installation of metal racks provides two ways:

- Installation on the step using anchor fixation.

- Installation in the end of the stage using brackets.

Installation in the first way begins with defining points for fixing racks. The step should make up a minimum of 30 cm.

- Twisted shurts in steps with a diameter of 16 mm, 12 cm deep.

- Anchor is placed in them, which will attack the first and last pillars.

- Top racks tensioning cable.

- With the flange mount, three recesses with a diameter of 120 mm are drilled, a depth of 8 cm. Dowels are inserted into them. The flange is attached by self-drawing, which in turn becomes the main for fixing the rack.

- The handrails are mounted with self-drawing over Balyasin.

When installing a balusne to the end of the stage, the distance between the marches should be about 70 cm. Balasine is attached to the end through two anchors.

- In the end of the stage there are two recesses.

- It is inserted in the anchor of the spacer type so that the ends are a bit performed.

- At the ends of the anchors, a cap nut, fixing two parts.

Concrete bassines: how to make

Balustrades from concrete are attractive and aesthetic. The material is not afraid of moisture, temperature differences. The manufacture of concrete balasine provides for the fill of the solution into the form. Molds from gypsum can be found in any construction store.

The casting of the racks occurs as follows:

- A concrete solution is poured through the hole in the form.

- The neck is tightly cleaned.

- The form is turned over several times for uniform distribution of the solution in shape.

- Two hours later, the form disassembled.

Concrete bales: how to install with your own hands

To install concrete balasine in the upper and lower part of the form metal fasteners are mounted. These are pins 5 and 10 cm for the lower and upper part, respectively. Often use fine reinforcement, which passes through the baluster.

The laying is welded to a metal staircase or mounted anchors if the staircase is concrete.

Conclusion

The installation of Balyasin is a responsible and complex process to which you need to be fully armed. Depending on the material of the baluster, the attachment method is selected. For metal elements, this is an anchor, for concrete - welding. But the principle of work is the same for all Balyasin.

Eliminate by the method of fastening lightweight materials, such as plaster and plastic. Products of them are allowed to be attached to glue. However, in this case, no strength from the supports do not have to wait.