Setting the dowels: Step by step instructions Building materials

Dowel is one of the most commonly used fasteners. As a rule, it is necessary for fixing fasteners into solid solid surfaces. A universal dowel is installed screw, screw or a nail that cuts it, which leads to friction. It was on this that the principle of operation of this fastener was founded. If you need to attach something to the concrete wall, then without dowels it is almost impossible. Therefore, they are often used in repair work.

Types of fasteners

Today there are various types of these fasteners, each of which differs not only by the material, but also the principle of fixation. Not so long ago, such fasteners were cut out of wood pieces and inserted into the hole. Today, these products are unlikely to have anyone. After all, now on sale you can find a dowel practically for all cases. The material of modern fasteners is plastic and metal. Most often, scoring nylon dowels are used. They together with self-draws are indispensable to work with any materials.

Consider some types of dowels available today on sale:

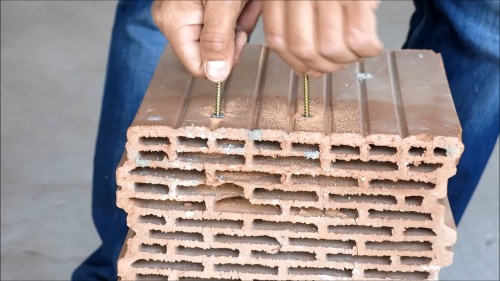

- Dowel for concrete. Polypropylene or nylon is used for the manufacture of such a fastener. These dowels are still well fixed to the stone and bricks. In addition to the fasteners themselves, self-tapping screws are required. For convenience, you can use a pistol for dowels.

- Material for the manufacture of dowels intended for sheets of plasterboard or gypsum fiber is usually metal (in rare cases of plastic). The same fasteners are well kept in cellular concrete. The use of data dowels implies the presence of self-tapping and building screws. Metal dowels for drywall are equipped with a tip in the form of a sharpened drill. Thanks to this, they can be installed even without the presence of holes in the working surface.

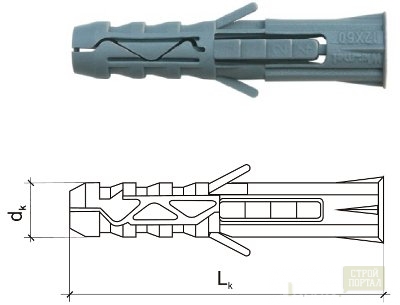

- For fastening materials in concrete, spacer dowels, made of polypropylene, often use. Such fasteners have special struts in their design, thanks to which fixation improves during installation.

- Mounting dowel from polypropylene. It is better not to use it for the outer decoration. The material used can crack at low temperatures. As for fasteners from a nylon, they can be used almost in any conditions.

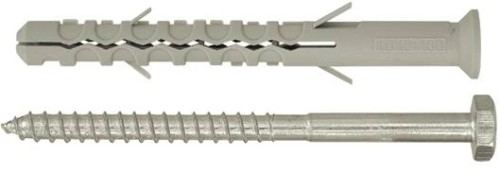

- Dowel nail. For its manufacture, it is similar to nylon or polypropylene. As for the nail itself, it is usually steel. To hold it there is a shot in the form of reverse cones. Such fasteners are used if it is necessary to fix the plinth, a profile of metal, window openings, rails, crates, boards. The dowel-nail usually sits on the wall of stone, brick and concrete. As a rule, these products apply when quick and bulk installation of small structures are required. Next, you can see a dowel nail in the photo:

- Frame dowel. Produced from metal. Actively used as fasteners for window and doorways. In addition, it is used if it is required to fasten the elements of the heat-insulating layer and the skin through the layer of plaster. They can be called dowels for thermal insulation. Two varieties of these fasteners are distinguished. The first are used to work with solid, and the second - with soft materials.

- Dowel to the wall (otherwise the facade dowel). The main materials for them is nylon or polypropylene. With these fasteners, you can attach anything to almost any wall. Only additionally will have to purchase a self-tapping screw with a diameter of 4 to 18 mm. In addition, it is required in advance in the wall to make a hole for a dowel of suitable diameter. The fastener is held in the well due to the presence of aimed muster.

- There is still a countering metal dowel, which is used to consolidate the racks of the crate at a certain distance from the surface. This distance is required in order to make the trim after a while. Thanks to the separated dowels and self-stakes, the position of the regulations can be changed at its discretion.

- Metal "butterflies" are ideal for attachment to various hollow structures. It is important that these fasteners can withstand quite large loads.

- For fastening window and doorways, a universal dowel is often used. It is still suitable for fixing crates and metal ridges. In addition to this dowel, such elements of the interior decoration are fastened as suspended ceilings.

- As a fixation of the insulation from the Minvati, another dowel is plastic or special fasteners from a plastic base. Fixation of material is carried out using a metal nail. For this fastener, it is necessary to open the wall in the wall. The mount is made on brick or concrete surfaces.

- The spacer device is successfully used as fasteners on hollow blocks and solid materials, such as brick and concrete. Fixation is performed using special mustache. They reliably hold fasteners and do not allow to turn in the hole.

- Dowel screws for mounting pistols. These fasteners have differences from standard dowels with manual installation. In some cases, it is preferable to use them.

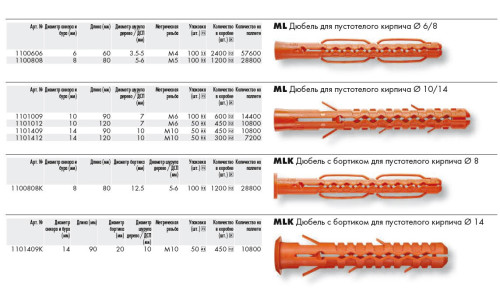

- Pour construction dowel equipped with a locking side. For its manufacture uses nylon. These mounts are applied when installing various building structures. The presence of locking colors does not allow fasteners to fall into the hole. Therefore, they are often used when conducting outdoor work.

- Dowel without sideboards are made of high quality polyamide. This type of fastening in its design has a hole, stationary upper part and longitudinal jumpers. This design allows the maximum to simplify the screwing screws. Due to the presence of an intimidate upper part, it is possible to exclude squeezing and cracking of the facing plaster on the surface into which the dowel screws. Such fasteners are considered more durable.

How to choose a dowel

Dowel is recommended to choose depending on the place where they will be used. Equally important to take into account the future load:

- So, to secure hard loaded structures, for example, such as hinged simulators and Swedish walls are best to take a dowel with a depth of at least 85 mm.

- For horizontal fixation in a concrete or brick wall, it is recommended to choose fastening elements, the depth of which is at least 30 mm, and the outer diameter of the dowel is from 7 to 11 mm.

- If the clamps are needed for a suspended ceiling, ceiling lights and other products, where the main load will be located below, then you should choose fasteners with transverse notches and spacers.

- If the dowel is selected under the ready-made hole, it is important that its diameter and the parameters of the fastener are fitted. In this case, it should be no less than the size of the opening.

- If the operation uses mounting fasteners, it is used to prevent the destruction of weak walls (this can occur at the site of the support) the dowel perfumes the role of a softening gasket. In this case, in solid surfaces, the fastening will be sufficiently firmly fit into fastening, so that the load applies evenly.

How to mount dowel

To work, you will need:

- electric drill,

- winning drill

- sharp nail

- dowel himself,

- insulating tape,

- small hammer.

When all tools are available, you can start setting the dowels.

Phased procedure for performing work:

- First, in the place where the installation of the dowels is planned, you need to make a label. This can be done, for example, with a ballpoint handle or a simple pencil.

- After that, at the markup point it is necessary to make a deepening. For this purpose, a nail, a knife or a pin is suitable. This hole will allow you to correctly put the drill from the very beginning.

- It is important that the diameter of the fastener approaches the dimensions of the hole and screw. It is best that fasteners entered the hole with a little effort. If the dowel does not meet these requirements, then he can hang out or move when you try to score it. Be sure to make sure the length of the dowel corresponds to the length of the used self-press.

- A situation may occur when the number of dowels is incorrectly calculated. It's not a problem. After all, dowels can be made with your own hands. To do this, take a wooden bar of the desired length. It is important that the size of the dowel approached the size of the fastener. Give the bar round cross section. It is desirable that it is thickened on top, and it is suled below, i.e. To make his form looked like a cone.

- Next, the drill of the desired diameter is taken and inserted into the drill. On the drill, it is advisable to make a mark corresponding to the depth of the opening. The label must be put at a distance, slightly more than the length of the dowel. To do this, fasteners are applied to the drill fixed in the drill and in the right place is cooled on it, which will be the mark of drilling boundary.

- Now you need to find a deepening on the wall. Drill must be kept perpendicular to the surface. In no case do not be tightened to the sides.

- When the hole is ready, it must be cleaned of the resulting dust and cement crumb. This can be done, for example, with the help of a vacuum cleaner.

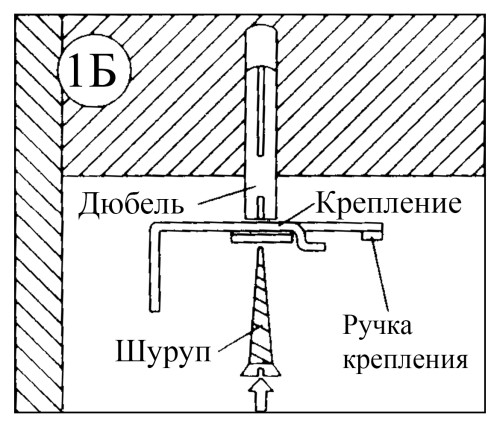

- It remains to insert a dowel and gently score it until it stops with the help of a hammer. The main thing in this matter is not to hurry and in no case do not hit the hammer too much. Otherwise, fasteners may be damaged and become unsuitable. After installing the dowel, you still need to screw in it (if it is a dowel under the screw).