Insulation isolon: characteristics of material and installation instructions Insulation

The effective thermal insulation of the structural design elements is necessary to save energy resources. The right choice of thermal insulation material largely determines the volume of future costs and affects comfortable accommodation in the house. Materialized material appeared in the construction market for several years ago. Its use on a third reduces heat loss. On the main properties of Isolon, about the rules of its installation and go on speech.

Content

Definition of cold sources

Thermal energy can leave the room through:

- windows and entrance doors;

- loggia or balcony;

- walls with insufficient thermal insulation.

To eliminate or substantially reduce heat loss, it is necessary to take measures to isolation of these parts of the construction construct.

The main differences of Isolon

The right choice of materials used is very important. Insulation isolon gives the following advantages.

- Isolon, the price of which is lower than other materials, allows you to achieve the desired effect with the smallest consumption of funds.

- Warming at home with insolon saves useful area: a thinner material takes less space.

- Folgized Izolon eliminates the need to use hydro and vapor barrier films, since itself has low vapor permeability (about 0.001 mg / m × h × pa).

- Low water absorption level (less than 1%) allows you to insulate the insulation of the room with particularly high humidity: bathrooms, paired, laundries, basements.

Types of Isolon

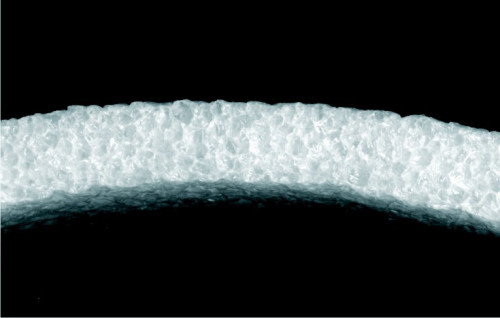

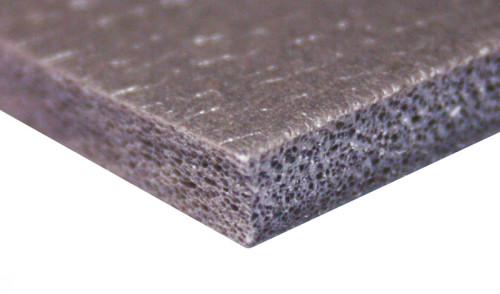

This material is a foamed polyethylene coming on sale in the form of rolled sheets, sleeves or rolls.

The thickness of this material varies from 1 to 50 mm. There are two types of isolon: physically stitched, with closed cells (PPE) and not stitched, gas-filled (NPE).

PPT isolon, whose characteristics are largely superior to similar indicators of other insulation, should be supplemented with the following items:

- low specific gravity (which is important for the upper tiers of light frameworks) - from 30 to 200 kg / m³;

- good soundproof properties (up to 68% of sound absorption);

- the ability to reflect thermal energy - up to 97%;

- softness and elasticity (allow you to fill in hard-to-reach areas);

- durability (ISOLON is not afraid of insects and does not rot) - service life exceeds 90 years;

- environmental safety (not toxic, does not distinguish the smell, does not irritate the skin, chemically neutral);

- wide temperature range of application (from -60 to + 75 ° C);

- universality of use (used in residential, industrial premises, in garages, warehouses, etc.);

- availability of material (ISOLON I can buy in any construction store);

- simplicity and ease of installation.

Isolon (sample photo is attached below) NPE differs:

- less density (in the range of 19 - 35 kg / m³);

- thick (up to 16 mm);

- sound absorption does not exceed 13%;

- thermal conductivity - at the level of 0.040 W / MK;

- parry permeability - about 0.001 0.001 mg / m × h × pa;

- water absorption - 0.2%;

- temperature range of application - from -80 to + 80 ° C.

Scope of application

You can use isolon in various fields:

- for insulation and noise insulation of car salons;

- in construction;

- in medicine - for the manufacture of a rake to orthopedic shoes, for packaging medical equipment;

- for the construction of barrier bon, making rescue vests (in river and sea transport);

- for the manufacture of sports and tourist equipment;

- for packaging fragile and faceing items.

Installation options Isolon

Problems of conservation of heat are relevant for both country houses and apartments in high-rise buildings. Methods of insulation are mostly identical, but there are some nuances.

Wall insulation

To work will be needed tools and devices:

- wooden rails;

- screwdriver and electric drill;

- stapler furniture.

The whole process is performed in the following sequence.

- To the walls using a dowel-nail vertically, wooden rails with a cross section 20 × 40 mm are installed. The distance between the rails is not more than 0.9 m.

- To avoid preliminary preparation of walls, under the rails are put on pieces of plywood or fiberboard, thus aligning the design in the level.

- The canvas of the isolon is fixed with one edge to one of the rails, after which it is stretched and attached to the stapler to the next. The work continues until all surfaces of the walls are covered.

- The jokes of neighboring canvases are rushed with a wide scotch.

Important: The airspace between the wall and isolon significantly improves thermal insulation.

Insulation Paul Isolon

This material can serve as a substrate when laying it under laminate or parquet. It improves sound insulation and at the same time warms the floor. At the same time, there is no need to use vapor barrier materials. Folgized Izolon is successfully used with the "Heating floor" system: laid on top of the foil layer heating cables or mats emit thermal energy exclusively into the room.

Instructions for the insulation of the floor with insulation consists of the following items.

- The base surface should be cleaned of dirt and dust, handle the primer.

- Before laying parquet, laminate or linoleum - make an aligning screed. In the case of a wooden floor - to make sure the fitness of the lag, if necessary - align them in terms of the level using substrates and additional backups. Check the boards, replace rotten and worn.

- To the concrete surface, the isolon is fixed with bilateral tape, to wooden - brackets (using a construction stapler). At the same time, the tank of the canvas is made from the center (diagonally) to the edges and on the sides - from the angle to the corner.

- For cutting of insolon, a construction knife is used. It is possible to restore the foil layer using a metallized scotch.

IMPORTANT: When insulating premises, foil isolon (see above) should be orientable to the reflective side inside. In this case, the thermal energy will be reflected in the living area. There should be no gaps and gaps in the material.

Insulation balconies

Instructions for insulation of balcony or loggia consists of the following steps of work.

- With the insulation of the walls and the ceiling, a multilayer design of foam and siesta is created. The first layer is stacked with a 5-mm isolon (foil-part side), then the foam, and the third layer - 3 mm isolon oriented similarly to the first layer.

- The seams between the sandwich panels are stuck with a metallized tape.

- Over the sandwich panels mounted a doomlet of aluminum profiles or wooden plates.

- A wooden or plastic lining, moisture-resistant plasterboard, OSB plates (depending on the finishing method) is attached to the crate.

- The insulation of the floor is performed similarly, but the sandwich panels are laid between the lags from the bars, laid at a distance of 0.5 - 0.6 m from each other.

- Two layers of moisture resistant plywood 16 mm thick, 40 mm boards or OSB plates are placed on the lags. Ceramic tile can be used as a finishing (chistoy) floor (stacked on glue mastic) or linoleum.

In order for you to have a better idea of \u200b\u200bthe progress of work on the insulation of the balcony isolon, we recommend reading the video, which shows one of the options for performing the work.