Air ducts for ventilation: selection and installation Climate

When arranging any room, ventilation is required. Installing the ventilation air duct contributes to the creation of a pleasant microclimate and provides high-quality air. Thanks to this, and work, and relaxing in a well-ventilated room is much more convenient - the human body does not have a lack of oxygen, pathogenic bacteria do not multiply, there is no feeling of loss of forces. But in order to obtain such a result, it is necessary to correctly carry out the duct of ventilation, choose the components suitable for a specific room and perform them. You will learn about all this from this article.

Content

Classification of air ducts

First of all, you need to choose the desired products. This can be done only if you own information that different air ducts are for ventilation, which are their disadvantages and advantages.

Criterias of choice

The classification of all air ducts is carried out in 3 main criteria:

- the material from which products are made;

- design features;

- type of section.

Important! Additionally, it is also necessary to consider the possibilities of the dimensional grid. But all manufacturers have such products have unified parameters governed by the norms of the current GOST:

- diameter - 100-2000 mm;

- length - Up to 20 m.

These are the basic parameters. Additionally, the area, perimeter, permissible hydraulic duct pressure, wall thickness can be taken into account. But all these parameters are calculated by specialists, based on the specific conditions of the problem.

Types of ducts in design

Depending on the device, the ducts of the following types are distinguished:

- External. These air ducts are attached to any walls in the form of suspended or appitable boxes. Collect such systems can be made of air ducts and fittings of various sections, shapes, lengths. In this case, it is possible to develop a laying scheme, based on the architectural features of the building, so as not to reduce its external attractiveness and ensure the high-quality air circulation.

- Built-in. Such products are used for installation inside concrete or brick walls. Distinctive features of the ventilation air ducts of this type are the ideal smoothness of the inner surface of the channel. This is necessary for the free movement of air flows. Periodic cleaning is carried out by means of a technological opening, which is located at the bottom of the air duct.

Types of air ducts by material

For the manufacture of air ducts use various materials:

- Metal. It is used both galvanized or stainless steel and aluminum alloys. Any type of metal air ducts is distinguished by strength, refractory, resistance to corrosion, strength while maintaining flexibility. Durability will be determined by the quality used for the manufacture of alloy. Regarding the cost - galvanized products will be cheaper.

- Plastic. Plastic ducts for ventilation are based on polypropylene. Due to this, high performance is achieved - strength, environmental purity, light weight, absolute inertness to moisture, wear resistance. The only thing that should be considered when choosing air ducts for installation in a particular building is the risk of deformation during mechanical exposure, as well as a low temperature threshold.

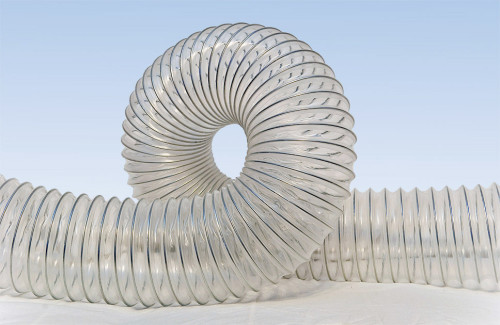

- Polymers. Of this composition, flexible air ducts are cast for ventilation, including corrugated. To give stiffness, aluminum or steel wire is additionally used. They can be used both separately and in combination with rigid metal or plastic products. When installing ventilation from polymer air ducts, it is necessary to take into account the high aerodynamic resistance of flexible parts, as well as an increased noise level during system operation. The ideal option is the use of flexible air ducts exclusively for small, hard-to-reach areas, for decoration of branches and bends.

Types of air ducts by type of section

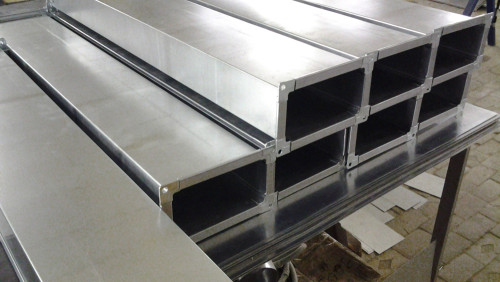

- Square / rectangular. Such ducts are used to harmonious interior design of various premises. Ideal such a solution if the height of the ceilings is small. But their manufacture and installation takes more time and effort. When operating, consider that rectangular ventilation ducts have high aerodynamic resistance.

- Round. This option is most widely used in any ventilation air duct systems. Such products are practical, have low aerodynamic resistance, convenient in installation and operation.

Installation of air ducts ventilation

When installing ventilation, you must pre-perform the following steps:

- Perform competent calculation of air ducts.

- Select the optimal way of connecting parts.

- Determine the type and number of additional fittings.

- Select the correct system of the air duct - with or without heat and noise insulation.

Additional insulation

To decide whether to make additional insulating protection of the air duct or not, consider the following recommendations:

- In insulation, there is a need if the air duct is laid outside the building or in an unheated room. This will help to prevent the formation and accumulation of condensate on the channels of air flow channels.

- It is advisable to accomplish noise insulation if the air duct is paired inside the premises of the following types: working offices, home care rooms, bedrooms, children's rooms. The method of creating noise insulation is chosen taking into account the set goal to the level of comfort and the design features of the air duct.

Important! Popular Ventilation Noise Isolation options - this is:

- The use of parts with a greater thickness of the walls or an enlarged section is applicable only for large, spacious premises. Note that the cost of components will be higher.

- Installation of special vibration insulating equipment - dampers, fans. For this, it may be necessary to somewhat change the diagram of the air duct line.

- Wrecking ventilation pipes with porous insulation materials. The cheapest and simple version of the option, but the external attractiveness of such an air duct can be reduced. Perhaps - will need an additional decor.

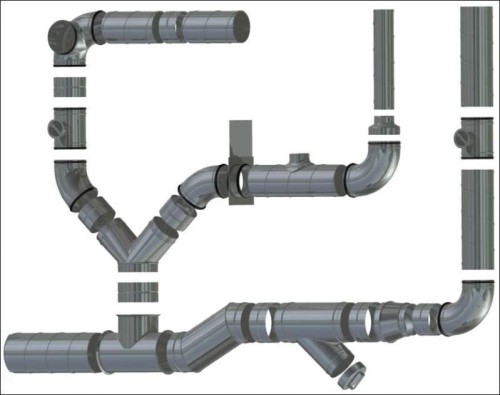

Choosing additional details

In each case, for the formation of the ventilation system, a different number of additional elements will be required. It can be:

- tees;

- taps;

- crosses;

- transitions;

- sings;

- umbrellas;

- plugs;

- ducks;

- throttle valves.

Important! If you cannot independently determine which parts are needed for your project, contact your specialists. Give them the planning diagram of your ventilation duct, and profile wizards will perform the necessary calculations.

Calculation of air ducts ventilation

One of the main stages of calculating the ventilation duct is the determination of the required amount of air for each room.

You can do this in 2 ways:

- Focusing on the number of people constantly staying in a specific room. This can be done according to the formula L \u003d n * lnorm, in which:

- L - the necessary performance (m³ / h);

- N is the number of people;

- LNORM is a standard air flow rate for 1 person (in a state of rest / sleep - 30 m³ / h, a typical value for the SNiP regulation - 60 m³ / h).

- Based on the rate of multiplicity by the formula: L \u003d N * S * H, where:

- L is indicative of performance (m³ / h);

- n - normalized multiplicity (1-2 - for residential rooms, 2-3 - for offices);

- S - Room Square (m²);

- H is the ceiling height (M).

Important! From the obtained values \u200b\u200bfor these 2 formulas choose more. If you do not want to do any independent counting, you can charge it to specialists, or focus on standard meanings:

- 100-500 m³ / h - for a separate room or apartment;

- 500-2000 m³ / h - for a private house or cottage;

- 1000-10000 m³ / h - for office space.

Installation of round air ducts

There are several ways to fasten round ventilation air ducts, each of which finds its application in modern construction.

- Coupling or nipple. The most popular option to arrange ventilation spans and their sealing. The essence of this method is that 2 separate duct segments are connected to each other by means of an additional, third, part. It can insert inside or attached outside.

- Flange. According to constructive features, the flanges of air ducts are small rims through which the connection of the desired parts is performed. Can be recorded both with the help of screws and at the expense of the spring mechanism. The use of a second option makes great easier and speeds up the installation work, while ensuring a good level of sealing. Additional fixation in this case is not required. Mandatory condition - the presence of flavors on the details of the air duct.

- Bandage. The most rarely used connection method. This option is a special device that is worn over the air duct on bending ends. The method of installation itself is very cheap and simple, guarantees a high level of tightness. But the manufacture of the bandages themselves is expensive. For this reason, they are not very popular.

Fastening rectangular air ducts

To seal rectangular ducts use:

- Flanges. The principle of registration is the same as in round air ducts, but in this case it is imperative that the flange is fixed. Otherwise, it is possible to send the parties or not a hermetically sealed connection. In order to fasten the flanges use rivets or point welding.

- Tire. Such a connecting part is the same flange, but with an additional tightening lock and gasket of porous tape, foam rubber, rubber or polymer harness. All gaps and angles are necessarily treated with a sealant, which is selected taking into account the aggressiveness of the inner and external environment.

Important! Separately, you can select methods for fastening for metal air ducts. They connect:

- false;

- welding.

Selection and installation of the air duct - video

Conclusion

Knowing all the features of the device of the ventilation duct, assemble the high-quality system is not difficult. But to ensure uninterrupted operation, do not forget to periodically clean the ventilation more convenient for you chemical or mechanically. Then there will always be clear air in your room.