How to insulate the floor cottage Plumbing

Wood has always been famous for its natural and good insulating properties, but even the most reliable wood floor in the country needs additional insulation. Floor without insulation ceases to act as a barrier to prevent heat loss. This is mainly due to natural wood movements - it shrinks over time, dries and cracks appear in the floor through which penetrate drafts. In addition, due to the large temperature difference between outside and inside the house there is condensate which is detrimental impact on the status boards. As a result, the once-robust and reliable floor is covered with fungus, mold and does not protect against the cold. To avoid this, you should insulate it qualitatively.

Content

Warming of foundation

Any house stands on the foundation - a monolithic, belt, column, reinforced concrete, brick or pile. And in any case it is necessary to insulate the foundation first, to the cold of the land was not transferred back side of the floor on the first floor of the house. Studies have shown that heat loss through uninsulated foundation and basement may reach 20%.

To engage in the basement insulation is best at the time of his favorites. Then you can place the insulation material on the outside, thereby saving more space in the cellar. But if the house is already built, or insulation from the outside of the foundation is too old and does not protect from the cold, it is necessary to insulate the basement from the inside.

As a heater, a foam, mineral wool can be used in rolls or plates (plates more expensive, but more durable and more efficient), extruded (foamed) expanded polystyrene or modern spray insulation.

How to insulate a basement:

- Clean all the inner surface of the basement (walls, ceiling) from contamination, old coating sticking fasteners, etc. If fungus was found on the walls or mold, it should be treated with a special anti-corrosion and antibacterial composition, which can be purchased in a construction store. Otherwise, if you just read the mold and put the heat insulation on the wall, it will grow again and reinfect the insulation. It should also be borne in mind that mold and fungi do not appear just like that - they are characteristic signs of missing or spoiled waterproofing, so after processing the wall, cleaning compositions should take care of the additional waterproofing layer. If not to do it, the insulation quickly will answer and loss its insulating properties.

- So, when the surface is purified from contamination, it must be aligned with plaster or classical construction mixture with sand cement. For its preparation, mix 3 parts of cement with 1 part of the sand and gradually dilute with water to the consistency of very thick sour cream (so that the mixture does not fall from the spatula).

- After drying the putty, treat the surface of moisture-proof primer. It can be purchased in a construction store or make it yourself. The recipe for self-made primer from PVA adhesion is very popular, which not only protects the walls from moisture, but also penetrates deep into the surface. To do this, take 1 liter of construction (non-stationery!) PVA glue, 8 liters of water and a little cement (1 trowel). Mix all the components to uniformity, leave for 15 minutes, strain through the gauze and proceed to the processing of the walls. Another inexpensive, but reliable way of waterproofing is the application of liquid bitumen mastic.

- When the primer dries, attach the heat insulating material to the wall. Depending on what you use, differing methods. So, mineral wool slabs are fixed by dowels, and the foam can be simply planted for special glue. However, professional builders recommend always combining these two types of fasteners for greater reliability, regardless of the insulation.

Important: If you use mineral wool in rolls or plates, you need to paro barrier, because this insulation easily absorbs moisture and can quickly dance. - After laying thermal insulation, you can enjoy interior trim. Usually on the wall and ceiling make a wooden crate to which plasterboard plates or lining fastened.

When you finish working in the basement, then immediately notice that the floor on the first floor of the house has become much warmer, and you have not even started working with him!

How to choose a heat insulation

Professional builders have been arguing for a long time on the best thermal insulation material for sex at the cottage, but in most cases not only the effectiveness of the insulation, but also its cost, and it is desirable that it be as low as possible. The warm floor in the country can be done using low-cost bulk materials, thermal insulation mats or plates, and if the means allow, you can organize polyurethane foam spraying and forget about drafts. Heaters on the market are full, but almost always the choice is repelled from financial capabilities.

There are a number of requirements for floor heaters:

- Little weight so as not to create an additional load on the foundation.

- Waterproof - the insulation must not let or minimally pass water, do not dance and provide additional waterproofing (ideally).

- Durability - Agree, no one wants to raise such large-scale work on changing the insulation once every 3-5 years.

- Fire safety - insulation should not easily flamm or maintain burning.

- Environmental purity.

If the financial position allows, modern insulation can be purchased, which are easy and quickly installed without the help of specialists. There is a solution for economical owners - traditional insulation schemes with cheap materials, however, they will have to tinker. Consider all the options.

Inexpensive insulation

If you want to save on construction, but not to sacrifice quality, there are several thermal insulation materials that are securely protected from the cold and at the same time they are inexpensive. For example, our ancestors were insulated with dry sawdusts. They can be purchased at the lowest price or get at all for free on woodworking production. However, in this case, it will have to strengthen the waterproofing, because the sawdust is easily absorbed by moisture, and when they repense it, they stop saving heat.

A more practical option is the sawing granules - this product is already modern production, the raw material for which is woodworking waste. Pressure sawdusts are pressed into small solid granules, which are not so easy to moisture and are preserved longer. Granules are treated with antipirens (means that do not allow easy to light up) and antiseptics. Basically, this material is used for the heat insulation of the floor along the soil. In addition, raw granules chemicals are excellent economical fuel for furnaces and boilers. They are also used as fillers for feline toilets, which speaks in favor of their environmental and safety.

Ceramzite has excellent thermal insulation qualities and is a favorite insulation of economical builders. These are foamed under the influence of high temperatures of clay granules, which practically do not absorb moisture and are able to give home heat for many years and even decades. The only lack of clay is its fragility, so caution should be taken when transporting. For high-quality heat insulation of the floor in the average latitudes of Russia, it is recommended to pour a layer of clay with a thickness of about 30 cm.

Another inexpensive insulation is a mineral wool in rolls without a corrugated shell or a foil layer. However, for it, as for sawdust, reinforced waterproofing is necessary. The same applies to rolled materials based on fiberglass, stone wool, slag.

Foam plates are also inexpensive, but they are very loved to spoil rodents who sooner or later come in any private house. In addition, the foam should be protected from fire - and even in itself it does not burn, but when melting, it allocates caustic smoke, which can lead to suffocation.

Expensive modern materials

If you want to spend high-quality insulation of floors in the country and are not constrained in the means, you have a lot of options, one of the other is better.

The most popular modern insulation:

- Vermikulite is the material obtained as a result of the processing of hydrated mica. It has excellent thermal insulation properties and is able to serve at least 20 years without loss of operational properties. It is an environmentally friendly and absolutely safe material for health and environment. It is used in homemade farming and gardening as fertilizer and drainage.

- Painoplex is produced in the form of light plates and is very easy to install. In fact, it is an ordinary foamed polystyrene foam (foam) with enhanced waterproofing abilities and greater strength.

- Penofol, isolate, thermal and other modified insulation in the form of plates or mats. They are based on polystyrene foam, glass gamble or basalt wool treated in a special way to increase wear resistance. Materials are distinguished by almost complete waterproof, durability, low thermal conductivity. A special foil layer on one side reflects heat and returns it back to the room.

- Equata and polyurethane foam also provide reliable heat insulation, but for their laying, special equipment will be required - a compressor, which will be under strong pressure to blow particles of insulation and tamper them on the surface. As a result, a dense layer of insulation is formed, which not only protects from the cold, but also serves as an additional waterproofing. Another plus - for eco-art and foam, you do not need to lay vaporizolation.

Wood floor insulation methods

SNiP 23.02.2003 clearly defines the regulatory magnitudes of heat transfer resistance and the requirements for heat engineering calculations, according to which you should navigate when choosing the thickness of the insulation. Many inexperienced self-taught builders mistakenly believe that the thickness will be thermally insulation, the better. If the insulation is too thin, then the house will be cold, if you are too fat - you will throw money into the wind. That is why it is important to choose correctly choose the thickness of the layer depending on the material of thermal insulation and the material from which the walls are made. Also, the climatic conditions of the terrain playing the climatic conditions in which the house is located. All these nuances are described in detail and are taken into account in SNiP.

If you do not go into the subtleties of heat engineering laws, experts advise building floors over a cold basement with a heater with a thickness of 12 cm for the middle strip, 20 cm - for the northern regions, and interlated overlaps to insulate the 8-centimeter layer.

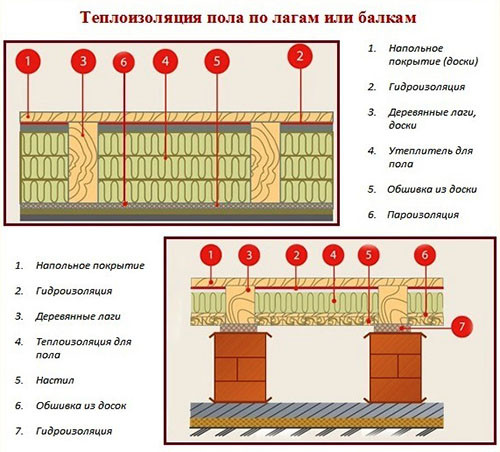

Warm wooden floors in the house are much more convenient than walls or overlaps of at least because their design involves the use of lag and rough floors. In the space between lags, you can pour clairzit, chips, gently and tightly put the plates or blew all the foam. Thus, the insulation of any material occurs according to the general principle - it is placed between lags and is closed with a fixed floor (in some cases additional hydro or vapor barrier is needed).

Low underground flooring

In houses with a limited size of the underground it is impossible to arrange the thermal insulation material as usual - between lags. To do this, you will have to dismantle all the flooring, because if this is just your case, prepare for labor-intensive work.

Sequentially performing work:

- Remove the finishing floor covering, numbering each item for subsequent correct laying in the reverse order.

- Carefully inspect the lags for faults, the appearance of mold, fungus, cracks, etc. Replace all defective elements. To do this, cut the problem area of \u200b\u200blags and replace it with a new bar of the same size and strength.

- To create sufficient space for laying thermal insulation, increase the lags in height. Attach the boards by both sides of each lag with galvanized wood screws.

- To the lower edges of the lag attach the bar, which will rely clean the flooring.

- Depending on the distance between the lags, prepare the segments of an inexpensive sawn timber for roughing. To do this, you can use even the building wood trash, if it is good quality and suitable sizes. The floor must be able to be smooth and with the minimum number of large gaps.

If you use the Unedged Board, sip it into fragments, 1-2 cm shorter space between lags. So you can freely put the draft floor. - Place the boards between the lags, but not too tight so that when driving the wood, irregularities and deformation are not formed. Attach the elements of the draft floor to the bars should not - they must lie freely.

- Next should be proceeding from that whether the floor need additional waterproofing or not. This is determined by the degree of humidity in the room, climatic conditions and requirements for the insulation. Specialists in any case are recommended to lay waterproofing between the draft floor and insulation so that the moisture from the ground is not given above. In some cases, it is possible to limit the vapor insulating membrane that will not miss evaporation from the ground to the house.

- It is necessary to sharpen the waterproofing by the possibility of a solid web, making the break on the walls at 15-20 cm. It is necessary in order to make a peculiar pallet in which the heat-insulating material will be safe. If you are using a rolled material, for example, a runner, warp it with a minimum of 5 cm, and join the joints with a width of 10 cm. To wooden lags and the walls of waterproofing, attach with a construction stapler with a step at 15-20 cm.

- In the space between lags, put or fall asleep thermal insulation material. The layer of the insulation should not reach the top of the lag for 2 cm to create a ventilation gap. If the insulation is too thick, and the gap does not work, you should make a counterclaim. For this every 40 cm, nail the rails perpendicular to lagas.

- On top of the lag (if the ventilation gap remains) lay vaporizolation or waterproofing. If you do a counterclaim, the protective layer should be located under it, that is, in any case, it must be laid on the lags.

- It remains only to re-assemble a numeric floor, and only after that you can cut a sticking piece of the lower waterproofing layer, which came into the walls.

This method describes how to insulate the floor in the country, if the construction has already been completed, but it is best to take care of the thermal insulation still at the time of design of the house.

Warming of floors over a high cellar

The nature of the actions in this case is no different from the previous one, except that you do not need to increase the height of the lag, dismantle the piston flooring and the stages of work should be performed in the opposite order. The only nuance is for insulation in this way it is impossible to use bulk materials - clayzit or wood sawdust.

Progress:

- Check out the beams of the underground underground and attach the waterproofing material to them with a construction stapler.

- Pribe the rails or support bars across the beams every 40 cm. If the basement in the house is very raw, then instead of wooden bars and the rails it is better to use a galvanized profile. It is not very durable, but also the load on it will be a little - only the weight of thermal insulation.

- If you use mineral wool, cut it with pieces of 2-3 cm wider than the distance between lags so that when installing, they stood up the veins and kept tightly without additional assistance. If you insulate the floor with plates, you have to call an assistant - one of you will hold the plate under the ceiling, the other is to choose the reiki holding it.

- The next layer is a vapor barrier membrane. It should also be killed to the beams stapler.

- To protect the heat-insulating material from rodents and parasites, between waterproofing and draft bed, a fine metal mesh.

How to insulate the floor, everyone decides for itself, but it is necessary to do this anyway. The warm floor at the cottage will keep warm in winter and will give coolness in summer, will reduce the cost of heating and electricity, will be the key to the health and comfort of tenants.